The Great British Make Off

This week, from posters to pancakes - how do the objects we see around us every day actually get made? We’re uncovering the science of manufacturing - from the very big, to the very small and the very complex. Plus in the news, why being a morning lark could protect you from breast cancer, and the project using drones and AI to keep tabs on ocean health.

In this episode

00:52 - Detecting cancer via the blood

Detecting cancer via the blood

with Dr James Brenton, Cancer Research UK Cambridge Institute

Cancer is one of the biggest killers in the developed world, and the later it is detected the worse the prognosis for the patient, so being able to spot cancer sooner is a top priority for researchers. A team from the Cancer Research UK Cambridge Institute have developed a new blood test that can track down eight different cancer types. Chris Smith spoke to James Brenton, from Cancer Research UK...

Chris - Cancer is one of the biggest killers in the developed world, and the later it's detected, generally, the worse the prognosis for the patient. So being able to spot cancer sooner is a major priority for researchers and doctors. A team from the Cancer Research UK Cambridge Institute have now developed a new blood test that can track down up to eight different cancer types. And James Brenton who is from C.R.U.K is with us to explain how it works. Now James, we’re familiar with the idea that cancer generally starts in a tissue somewhere.So what's the blood got to do with this?

James - Well one of the biggest advances in the past 10 years is the realization that we can detect the faulty DNA that's inside cancers in the bloodstream, and that can be used as a non-invasive liquid biopsy test to try and pick up cancer either in patients who have it or potentially as an earlier diagnosis method.

Chris - So when a person has cancer in any part of their body the abnormal cells there, are spilling DNA over into the bloodstream and that's what you're saying you can go for.

James - That's right. In fact, this is a very interesting part of the process which we don't fully understand. As cancer cells die they release their DNA into the blood. That means you can detect it in the blood. The problem is, is that our blood has got DNA from normal cells in it, particularly from the white cells in the bone marrow. And this is in a huge excess compared to the amount of faulty DNA that comes from the cancer cells.

Chris - So you’re literally doing a DNA needle in a haystack and it's a giant DNA haystack.

James - Absolutely. And in fact the advance we've done, is to guess that perhaps there might be specific size differences in the DNA from the cancer as opposed to the normal DNA.

Chris - What do you mean by size differences?

James - So we know that DNA from normal cells is about 166 base pairs long.

Chris - Genetic letters

James - Indeed. So the size of it is a very specific size. But then if we look at DNA sizes from cancer, these sizes are significantly shorter; between 90 and 150 base pairs. That's again the unit

size of a piece of DNA. And so our advance, is really by using a very cheap test we can significantly improve our ability to detect that DNA, by pulling out specific sizes of the DNA from the blood.

Chris - To just summarise it then, basically if I take a blood sample from me, I assume I don’t at the moment have cancer, and you look at the DNA that's floating around in my bloodstream you will see fragments of the DNA that's come out of dead or dying or lysed cells, and on average it's going to be 150 or so genetic letters long, those bits, and you're saying if I had cancer though you'd see another population of bits of DNA there which were much shorter.

Chris - Do you know why they should be much shorter?

James - So we know that when normal cells die, the DNA in those cells is broken up by a process called apoptosis. And that's a programmed way in which the cell breaks down all its components for recycling, because the enzymes that break down the DNA work on particular sizes because the DNA itself is very very long and it's wrapped around large proteins. What happens when those normal enzymes the, sort of, turnover engines of the cell work, they chop it down to 166 base pairs or thereabouts. However in cancer those processes may be slightly different and that's because the DNA in the cancer has got different marks on it. That's called methylation and that may affect the way in which that DNA binds to these proteins, the nucleosomes that are responsible for protecting it in a normal cell.

Chris - And how good is this as a test?

James - So you talked early on about a needle in a haystack and that's really the problem that we have in front of us. We can detect, with normal methods of sequencing the DNA, probably down

to about 0.5 percent of DNA, if it's cancerous. With these new methods of, essentially, pulling out specific sizes, we can increase that by over 2 fold in at least 95 percent of cancer patients and over 4 fold in about 10 percent of patients with very significant changes in some patients. So those differences make a huge difference to picking up very important changes in the cancer that may be responsible for changing treatment or for picking up a cancer early.

Chris - So you could use it either, as a diagnostic screen. You could just screen people's blood to see if there's a cancer there in the first place. But equally you could use this if I'm on treatment for example you want to keep an eye on me to see if I've responded and if I've continued to respond or if my cancer's coming back, it would be a sensitive way to get an early warning sign.

James - So that's exactly right. So we've shown that using this cheap method means we can pick up a cancer recurring earlier than other methods of trying to detect this circulating cancer DNA. So that means that for the patient there may be earlier options. Well the patient may be better or fitter when we start treatment.

Chris - Which cancers, I mentioned earlier you said eight, but which cancers are you going for with this?

James - One of the important advances is that our method also improves detection for difficult to detect cancers, particularly those associated with brain cancer, pancreatic cancer, renal cancer, and ovarian cancer.

Chris - So these are things that tend to present late aren’t they, cancers we pick up when often they're quite advanced?

James - They are, and many of those cancers don't have easy ways of using other methods to detect or screen for them.

Chris - Is this test ready to go now or is this at the very early stages?

James - So I think the methods we've now discovered are applicable by everybody around the world. You don’t need expensive methods to apply it. And I think what will see now is validation. In other words testing our methods in other people's studies to show that it works and bring it into the clinic.

06:47 - Finding dugongs with drones

Finding dugongs with drones

with Amanda Hodgson, Murdoch University

If you stick a microphone into the water in some parts of the Indian and Pacific Oceans, alongside the snapping sounds of prawns, you might hear munching and squeaking noises. The animals responsible are dugongs, also known as “sea cows”. These are marine mammals; they weigh in at over a quarter of a tonne, and, like their land-dwelling counterparts, they also eat grass - in this case seagrass.

But, apart from being an endangered species worthy of watching in their own right, dugongs are also a very useful indicator of the health of their local marine habitat; and Amanda Hodgson, at Murdoch University in Perth, Western Australia, has just won a $250,000 Google Impact Challenge award for her work using drones and artificial intelligence to count dugongs all over the world. She told Chris Smith why this matters…

Amanda - Dugongs feed exclusively on seagrass and they actually occur throughout the whole Indo -Pacific. But unfortunately they're vulnerable to extinction largely because their seagrass habitat is disappearing and that's something that we should all be very concerned about because we all need seagrass. Seagrass feeds 3 billion people and also is extremely good at storing carbon. People don’t realise just how vital seagrass is because it plays a part in a lot of species life cycles so even things like prawns which we a lot of us love to eat, seagrass is essential. So without seagrass we wouldn't have prawns.

Chris - So we could try really hard to save dugongs but if we don't save the seagrass then we’ve got no dugongs anyway?

Amanda - That's exactly right yeah. So really our idea is basically to be getting people's attention on dugongs because dugongs are an excellent barometer for seagrass health so if you don’t have seagrass you don’t have dugongs. So you know, if your dugongs have disappeared, you should start worrying about the seagrass.

Chris - So how are you approaching this, and how are you going to tackle a problem that’s not just one little geography, this is a worldwide problem?

Amanda - Yeah it's really difficult because the best way for us to monitor dugongs is to do aerial surveys; that, traditionally, has meant putting a team of five people in a very small plane flying very low and very slow over hundreds of kilometres. Quite risky for that team and very expensive and it requires significant expertise and all of those things don't occur in most of the countries where dugongs occur. So, to overcome that problem, we have developed methods for using drones instead of planes to do that. So just basically using drones to take aerial photography of the ocean and then counting dugong images.

Chris - Have drones got the range though? How big are these drones?

Amanda - So I originally have trialled some pretty high end drones - the same drones that the military uses - and they work very well; they have the range and the endurance, but they’re not within their research budget of most people! So with large scale surveys we really need some new, cheap drones to be developed that can have the same capabilities. But we’re also developing methods to do more small-scale surveys, and in a lot of areas actually dugongs occur in quite small pockets; so using drones that are off-the-shelf - that people in developing countries can afford and have access to. And were developing methods to use those. So that’s really simple and user-friendly.

Chris - So how will it work then? You will deploy some drones to a geography; they’ll do the aerial survey, take photos, and what can you extract from the photos, ah that’s the dugong?

Amanda - So that's the tricky bit! Originally we were having to just review the images ourselves, which takes a long time. So what we've done is developed a dugong detector which uses artificial intelligence and machine learning to pick thd dugongs out of the images automatically; and so that has reduced the time it takes to view the images by 95 per cent.

Chris - How do you know you’ve not spotted the same one multiple times as the sort of “Where's Wally” of the dugong world? Say it keeps popping up all over the place: how do you know you're not just double counting?

Amanda - Well that's all part of the survey design so we have to make sure when we design the survey that we're designing in a way that we are unlikely to come back and see the same animal again, and we actually usually sampling of an area rather than covering the entire area. So we maybe survey 10 per cent of that area we're interested in, and then we extract from that an estimate of how many dugongs there are.

Chris - And have you got a sort of "backend" for all of this so all the data coalesces, so that then you can bring together all of the different sampling sites around the world so you get a more global picture?

Amanda - Well that's exactly our mission at the moment. Our vision is to create a dugong detector online hub, which would support people doing surveys all over the world so they would have access to a tool that would help them design their survey and choose the appropriate drone. And then they would download the dugong detector, which would process all the images for them. And we're going to expand the dugong detectors so that it also classifies images according to the environment that you can see, the images including the seagrass you can see there. Then they can upload all of their data from the dugong detector to an interactive map on the hub and they'll be able to create their maps but also to a global database.

Chris - So it's got benefit for keeping eyes and tabs on dugong numbers and how they're getting on in the environment, but then it's a proxy marker for probably the environmental health in those regions isn't it?

Amanda - Yeah absolutely. So if you’re able to do some surveys regularly and you know the dugongs have always been in this area but suddenly disappeared then that's a warning basically you need to go and check what's happening with the seagrass.

Chris - And it does that mean then that you can spot areas that are either very good, and so you can then ask why are those areas so good, and equally you can spot areas which clearly show a downward trend and you can ask well what's different and why are they showing a downward trend and you can begin to tailor your interventions a bit more?

Amanda - That's exactly right. Ultimately it gives local authorities in their areas the ability to know what are the areas we really need to protect and what are the areas we really need to focus on to mitigate any impacts on the dugongs and the seagrass...

13:46 - Morning people reduce cancer risk

Morning people reduce cancer risk

with Dr Rebecca Richmond, University of Bristol

Are you able to bounce out of bed in the morning and greet the sunrise, or is it an uphill struggle to force yourself into the land of the living each day? It turns out that whether you’re a morning-loving “lark”, or a darkness-craving night owl can have far reaching effects. By studying data from 500,000 individuals, researchers at the University of Bristol have found that women who are “morning people” have a much lower risk of breast cancer than those who aren’t. But why? Adam Murphy spoke to Rebecca Richmond who presented the work at National Cancer Research Institute’s Cancer Conference in Glasgow.

Rebecca - So of interest to our particular study was looking at sleep characteristics in relation to breast cancer risk, and we looked at three specific sleep traits of interest. So one of those was an individual's preference to be a morning or an evening person. A second one was we asked individuals about how many hours of sleep they were getting each night. And finally a question also asked about insomnia risk - so that's difficulty getting to sleep or waking up in the night. In these two large studies we looked at these questions and we also looked at genetic variants which were associated with these various sleep traits and looked at the contribution of these towards risk of breast cancer. What we found was individuals reporting to have a preference towards the morning were actually protected against risk of breast cancer.

Adam - How much were they protected by?

Rebecca - In terms of looking at the extremes, so definite morning people versus definite evening people, there we actually showed a 40 percent reduction in risk of breast cancer.

Adam - That's a fairly massive reduction for something as taken for granted as sleep.

Rebecca - Yes so it's quite interesting findings. I suppose we have to also put this in some context in terms of actually looking at absolute risk - so these 40 percent estimates are relative estimates. In terms of a bigger perspective, we know that one in seven women will develop breast cancer at some stage during their lives. So it's very important to recognize that although sleep may be one potential modifiable risk factor actually there are some other very important risk factors which we know about. So it's very important to, for example, maintain a healthy weight, to not smoke, and to drink in moderation. And so at this stage it is quite early findings with regards to the actual impact of sleep on breast cancer. But this is where it goes some way towards putting sleep on the research agenda for breast cancer.

Adam - Do we have any idea why a preference for sleep time is a factor in this?

Rebecca - So it is quite complicated to think about what it actually is about being a morning person that protects these women. In terms of potential mechanisms, one quite well known hypothesis is regarding the effects of light at night which might be a potential indicator as to why those individuals who reported to be evening people were more at risk. So, the idea behind this light at night hypothesis is that individuals who stay awake later into the evening have more exposure to artificial light and that this can cause disruption in hormone levels which might put these women at risk. Some other potential links between morning and evening preference in breast cancer relate to potential differences in metabolism and also differences in other lifestyle behaviours.

Adam - Does that imply then that shifting your behaviour, shifting when you sleep, would help or is it a genetic thing that we can’t really affect?

Rebecca - We did look at this and the genetic component making up morning or evening preferences is relatively small, so around 10 percent. So that indicates that this behaviour is modifiable. But at this stage we think it's too early to really say that we should advocate that women, for example, get up earlier. And we need to try to make this distinction between what it is about morning preference compared with actual behaviour. Because there is some argument to say that individuals who have a tendency towards an evening preference, by disrupting that, by making them get up early, actually that could lead also to increased risk because there’s a sort of misalignment between their biological clock and their kind of social clock as it were.

Adam - What is next for you in your group? What's the next plan?

Rebecca - So there is evidence to suggest our body clock is also potentially important for other conditions and other diseases, and other types of cancer have also been suggested to be potentially impacted by these various sleep related exposures. So we're going to also, hopefully, look at other types of cancer. And also other types of diseases using the same type of methods that we've been applying in this study and look at those particularly at risk of disease.

18:35 - Pesticides affect bees inside their nests

Pesticides affect bees inside their nests

with Dr James Crall, Harvard University

Neonicotinoids are the world's most popular pesticides; and they're often added to seeds so that, as plants grow, they're protected from insect attack. But the chemicals also get into the plant's nectar, meaning that harmless insects, like pollinating honey- and bumble bees, are inadvertently exposed too. This affects the bees' foraging behaviour; but what about their behaviour when they get home, inside their nest? No one knew, but now, speaking with Chris Smith, Harvard scientist James Crall has developed a way to tag individually an entire nest of bumble bees so he can follow what happens to their behaviour when they're exposed to neonicotinoids, and it's not good news...

James - Neonicotinoids mimic chemicals that work in the insect’s central nervous system and they were developed in the late 80s and came into the market in the 90s are now really widespread. They are the most common group of insecticides used across the globe and over the past few years we've realized more and more these compounds, even at low levels, they're still having negative impacts on bees. So what we were interested in understanding is a little bit more of why that might be happening. And in the past 10 years or so we've got a really great understanding now, of the ways that these compounds affect foraging behaviour. But what's going on inside of the nest, all of this important behaviour within colonies has really been kind of a black box, and so what we wanted to do in our work is understand what these compounds are doing to that social life of the colony within nests.

Chris - Is that easy to do?

James - Yes and no. So it's easy if you're willing to have a few angry bees in the face. It is easy enough to open up a colony and look inside of it. One of the challenges of watching individual bees is it's really hard to scale up in a few different important ways. So one is of course, it is hard to focus on 100 different things at once, so if there are 100 bees in a colony it’s really really hard to understand what every one of those is doing at the same time. It's also really hard to do it for a long time period. And it's also really hard to do across multiple colonies and so what we wanted to do in our work is get some automatic tools that let us do that work without having to look by eye. What we do is outfit every bee in the colony with a special little paper backpack, sort of like a very simple QR code that we've made really simple so we can make it really small, and just glue it to the back of a bee. That lets us look inside of the nest with a camera and identify the location and movements and interactions uniquely identified workers, automatically, without having to look by eye.

Chris - So basically all the bees are tagged in a computer via a camera, and can watch where individual bees go, and what they do and presumably then you can compare bees that are exposed to pesticides and those that aren't and you can ask that crucial question: Does this make a difference to how they behave?

James - That's exactly right. So one of the first things that we wanted to do with this technology of being able to look inside of a nest and follow what individual workers were doing, is we pull out individual workers, feed them different amounts of a really common neonicotinoid pesticide called imidacloprid, and we can feed different amounts to workers that have been brought out of the colony and made a little bit hungry. So they're more likely to eat a little artificial sugar, and then we can put a controlled amount of this compound in there. And so within the same colony we can feed different bees different amounts of the pesticide. And because we know that individual behaviour of every bee in the colony, what we can look at is the changes in behavior within individuals. So is a specific worker acting differently and behaving differently than it was after we give them a little bit of this pesticide.

Chris - And is the exposure what we would dub field relevant. In other words if these were bees in the wild and they were foraging in an area where a farmer had used some of this particular type of neonicotinoid, would the exposure that you’re giving to them be equivalent to what they would probably encounter naturally?

James - Yeah that's a great and really important question for this kind of work. The concentrations we are looking at are in the range that we expect to see in nectar and pollen in plants that have been treated months before, as seeds, with these compounds.

Chris - And when you do this, do you see a change in the way that the bees behave?

James - Yes we do. So we see a couple different things change, so one thing is that workers within the nest move away from the nest centres. So they seem to be a little further away from where a lot of the centre of action of the nest is. They're also less active and they also interact less with nest mates.

Chris - And do you think this makes a difference though? Because some of these changes they sound quite subtle. Does it make a difference to the fitness of the nest?

James - Yeah we think it is likely to have important ties to colony function in the long run, even though we didn't directly look at that in this study. There is now a lot of other really great studies and great work showing that even these same concentrations that we studied here, can negatively impact the colony growth. And so we think these changes in behavior, for example bees spend less time nursing and doing other kinds of nest care. All of those are really important for the growth of a colony. So this work suggests that we might be disrupting a lot of these other important behaviours within the nest and not just foraging.

Chris - So what should we do about this then? It sounds to me like we have pretty incontrovertible evidence that these compounds, that are being routinely used, are very disruptive to at least some species of insect. So can we justify continuing to use them?

James - I think that's a really important question, and I think at the very least we certainly need to be having a very serious conversation about the role of these compounds in our food systems. We know for sure that these compounds can have negative impacts but there are still huge open questions in terms of different species, how they vary over time and place. So I think we need to be thinking very very hard about the benefits that we get from using these compounds and what the clear risks are.

What is manufacturing?

with Professor Sir Mike Gregory, Cambridge University

How do engineers, scientists and technologists actually make the products we see around us everyday? Georgia Mills spoke to Mike Gregory, former head of the Institute for Manufacturing at Cambridge University...

Mike - Well, we really mean a cycle of activities from understanding people's needs or wants. Working out design that will do that job, then working out how to make things, and deliver them, and service them, and to do all of that without using too much material or too much energy or without making a mess. Of course in the middle of that cycle is the really interesting bit of making and shaping materials. How exciting can it be to dig up some material, some earth out of the ground, fairly special earth, and turning it into an aeroplane so that making bit, is really exciting but it's worth remembering that manufacturing is not just about planes and cars, it's about food, and medicine, and buildings.

Georgia - And I know we have some food in the studio, and I’m going to ask you about that in a second. But what are some of the common manufacturing methods that we use?

Mike - Well there's a raft of them. Many of them, you’ll be familiar with. We can cast things into moulds, I wasn't thinking of cake necessarily, but cast iron or we can squirt things into moulds like plastics, we can extrude long strips of things through dies to make aluminium parts. We can bash things into shape by forging, or we can machine them by cutting, either with machine tools, or perhaps with lasers these days. And increasingly we can make things additively by adding on small amounts of material to make extremely complex shapes.

Georgia - Right so, building things up, cutting things down, or just sort of bashing things together. Do we have much manufacturing going on in this country at the moment.

Mike - Well we do quite a lot. There’s a bit of a myth that we don’t have any. Hence the reason for your question I suspect, but in fact, we're still the sixth largest manufacturer in the world. We have the second largest aerospace industry. Rolls-Royce Aero engines are on 30 percent of the world's new aircraft. We make all the wings in this country, for Airbus planes, all the major carmakers have plants here, and we have global food industries, medicine industries, and these days a lot of attention being paid to making buildings in factories, and assembling them together on site rather than putting one bit of clay on top of another as we do traditionally.

Georgia - I’m imagining a kind of flat pack house now. That's exciting. So what about robots? How have robotics changed our manufacturing efforts?

Mike - Well as you appreciate, they don't look much like Star Wars robots. Really, they're there to move things around and that's really useful. Jobs which can be very repetitive, which make us tired or sometimes pretty bored, can often be replaced by robots if they're reasonably standardised. And so a robot is a kind of automation. It doesn't have hidden arms but it does have very accurate positioning capability and can work fast without getting tired or getting worn out.

Georgia - Right, and Sam, who put the program together was telling me that even the most ordinary things have a good deal of robotics involved in them. I have here with me some Scotch Pancakes, I’m going to open them here and eat them while I’m asking you about them. Well I would if I could actually, it’s quite tough!

Chris - Would you like me to help.

Georgia - Would you open them for me please?

Chris - I'm offering cause I'm hungry actually, right here we go. Shall I resort to a key?

Georgia - Let’s ask about the manufacturing of that packaging!

Chris - Unopenable packet! I’m in, there you go!

Georgia - Brilliant. Here we go. So these pancakes have these little rings on them and Sam is telling me that even pancakes have robots involved in making them.

Mike - Well it's a great example of robotic assembly. You tend to think of robots making mechanical parts. But really important for food, because it's exactly that kind of process that’s very repetitive. You have to do it very fast and very reliably. And so that ring you see on the pancake is where the suction cup went on to pick the pancake up and put it on the assembly line.

Chris - It's the sort of ring you get, if you imagine putting your cup down and you get a tea ring if you spill your cup on your desk there's a ring that sort of size and shape on the surface of these little pancakes. And that's where the suction went.

Mike - Exactly.

Georgia - The plunger just went along, picking up all the pancakes. Would you like one Mike?

Mike - Would you have any butter to put on it?

Georgia - No I don’t I’m afraid. Just plain. And why are we still innovating in manufacturing? Don’t we already know how to make things? Why is this important to invest in?

Mike - Well, although a lot of processes have been around for a long time, there’s a lot we can do to make them better. So whether it’s casting or forging, we can make them faster. We can make them cheaper. We can make them more accurate, and that’s always worth doing, but of course, there are new processes emerging, like additive processing that we mentioned before and that will enable us to do things that weren't possible before and to do them in economical and practical ways.

32:48 - Additive manufacturing

Additive manufacturing

with Professor David Wimpenny, Manufacturing Technology Centre

One recent major development in the world of manufacturing is additive manufacturing, or 3D printing. The Manufacturing Technology Centre in Coventry has a team at the cutting edge, and David Wimpenny - the technology manager - spoke to Chris Smith about how additive manufacturing is a real game changer...

David - It's so different than conventional manufacturing methods. As Mike already said, we’re used to making parts by injection moulding, where the shape of a part is controlled by tooling, or by taking a block of material machining away to form the shape. Both those techniques have drawbacks in terms of the waste of material that's formed, the geometrical flexibility, and the need to have fixed tooling.

Additive is quite a simple technique. You're just making objects by depositing layer upon layer of material on top of another. It allows unlimited flexibility in terms of the part geometry. And of course another advantage, you can print parts on demand, you don’t need to have the lead time and time to separate a mould tool, for example, so it's really a game changer. You can imagine a part that's being formed where across each layer can be different distribution of materials, and layer by layer that distribution can change. There is no process that I can think of that allows that flexibility and the potential that brings with it.

Chris - I was going to pick up on the point you made about making these things to order. Of course, when we engineered or made things in the past, it was so expensive to make prototypes that actually often things were very very slow to develop but if you can 3D print things you can try lots of different ideas very very cheaply.

David - Absolutely, your lead time between thinking of an idea and be able to bring it into production is very short. Now we have a whole raft of new companies where you got an entrepreneur that's maybe even sat in his bedroom designing something and the next day could potentially be asking your company to print it, and doesn't even have the printing equipment itself. The printing equipment can be based anywhere in the world. So this is flexibility we've never seen in manufacturing before. And, of course, another advantage is that we can print things that are customized to individual people. printing things like customized implants for surgery for hip surgery and also many people who've got dental work will have implants made for them especially by 3D printing that match specifically what they need. So it's that flexibility we dont get with conventional manufacturing.

Chris - People are often familiar with 3D printers using plastic, and things like that, but actually Rolls Royce hit the headlines a couple of years ago when they flew apart in an engine which was the biggest flying 3D printed part. They printed a whole chunk of jet engine and they used obviously metal for that so tell us a bit about how we can use different materials in a 3D printing environment to make very specialist components.

David - Some of these materials, particularly in the aerospace industry, titanium alloy components, are very commonly used. But it’s quite a difficult material to process, it’s hard to machine and it’s also very expensive. If you’re using these more exotic materials, you don’t really want to waste that material and so additive manufacturing offers the potential. It’s not just complex shapes but also not to waste the material, you can add and also print the material exactly where you want it.

Chris - So how does it actually work? If I wanted to make a very complicated bit of engine out of a very costly material, how do I do it?

David - Yeah, that’s a good question. So normally we take a powder a fine powder, we lay it down in the very thin layer and then we use a laser or an electron beam to selectively melt that powder to form a slice through the object. And then this process is repeated layer upon layer upon layer to effectively form the entire component. It starts as a powder and ends up as a solid metal object.

Chris - Structurally, has it got good integrity? My reason for asking this is that I have been fortunate to go to Rolls-Royce precision casting facility up in Derby, and they grow parts for their jet engines out of single crystals of the metal. So when they make the cast they pour it into a very hot mold and then they start this little crystallization process at one end of the object and it spreads through the entire thing they’re making. And that gives it enormous strength. If youre just fusing tiny little bits on each time you get the same single crystal, same strength that you would get?

David - We’re struggling with the crystal at the moment, that's one area where this still some work to do. But one thing we do get, compared to conventional forgings, is that we can get really fine microstructure. The material itself has better properties than you get with some of the conventional manufacturing techniques and certainly better than castings where we're used to quite large defects, in some cases for certain complex parts.

You are getting a better, what we call, metallurgy from the materials you're using but we're still struggling to get the quality you get from a single crystal but, of course, in the future it may not be utilising metals at all. We might be using ceramics advanced ceramics for for these high temperature, high corrosion, areas of a gas turbine. As we increase the temperature, we get more efficient engines. Ceramics are very hard to form conventionally so additive is yet another method to form these difficult to manufacture materials.

Chris - I've not heard anyone talking about 3D printing ceramic materials before. So if you say they're hard to work with, why are they hard to work with, and how will we do this?

David - Typically, they're very brittle, they're difficult to shape. And with additive manufacturing, we can take apart materials in the form of powders, and shape them. It also makes them less sensitive to cracking during processing. So I've got colleagues working at the moment on using machines where we lay down a layer of fine ceramic material, and we print a binder using an inkjet print head. That forms what we call a green component, effectively a loosely bonded ceramic component. That can get be heated and fired in a furnace to make a fully dense component. That revolutionises the shape of parts that can be made by ceramics. There's also potential to mix ceramics that are very hard to mix using conventional bulk processes. It could potentially revolutionise the ceramics industry, but ceramics is still lagging behind the plastics and metalic additive manufacturing processes because they've been around longer and more money has been dedicated to them. But ceramics is the next thing coming through and we're starting to see really important developments.

Chris - So what kind of industries would you be talking to then? I can imagine medical - implant makers might find a use for ceramics because people are worried about the wear parts of metals from say a hip replacement, but what else?

David - Anything where you've got high temperatures and a corrosive environment, ceramics are a big bonus. There are applications at very high temperatures, again in aero engines, particularly space applications. The rockets used in sending space craft into space require very very high temperature materials, and often the current materials we've got can't reliably last long enough but with ceramics you have that extra heat resistance.

40:53 - Lasers: making the micro

Lasers: making the micro

with Dr Francisco Orosco, Cambridge University

Engineers can use lasers to make things on a tiny scale, but how? Sam Brown spoke with Cambridge University's Francisco Orosco to find out...

Sam - When you hear the word lasers, what do you think? Sci-Fi battles in a space opera? Perhaps James Bond about to be cut in half? Well, while people have looked into these uses, really lasers are much more commonly used for helping us make things rather than destroy things. This month Samsung have announced their foldable phones and the flexible electronics inside require powerful and precise lasers to cut and drill. So, I, Sam Brown took my phone with me to the Centre for Industrial Photonics at Cambridge University to find someone who could tell me which bits are already made using lasers.

Francisco - Hi, my name is Dr. Francisco Orosco. I work here mainly using industrial processes that use laser as the main source.

Sam - So you look like you’re busy here, what's happening?

Francisco - So today we’re going to be doing a little bit of marking for you, we’re going to be putting the logo of The Naked Scientists into a little piece of steel for you. So what we're going to be looking at is a laser system that uses very fast moving mirrors to reduce the area of the laser to a very small spot -talking around half the size of the width of the human hair. And then from there, the material we’re going to put underneath, which is stainless steel today, that will absorb the laser energy and then it will heat up and we'll be able to remove some material and then you'll see the Naked Scientist logo onto that piece of steel.

Sam - Fantastic. It's behind quite a sturdy looking safety screen, why is this here?

Francisco - We have a fully enclosed system and the only way to look at the laser is through that little window. So that window reduces the intensity the laser has so you're able to see it, otherwise our eyes or our skin could get damaged from the laser.

Sam - Now that I felt sufficiently safe we fired up the laser.

Francisco - All right let's kick this process off.

Sam - As the marking began we could see the steel glowing brightly as it was heated. Dr Orosco told me the maximum laser power being used was one kilowatt. That's a million times that of a laser pointer you might have in a classroom or use to play with your cat. But how exactly does a laser work?

Francisco - Alright so the process that we’re looking at here: the laser is focused onto a very small spot, and it will heat up the material, and it will remove some of the material by heat and then the rest of it you are basically going to have a change in the colour. And that's what we're going to see today. So it will remove a very thin layer and then also heat up the metal, and that's why we have that marking and that's why it's permanent. You aren’t going to remove it with your finger or if you scratch it because it's very durable and it's hard to remove from the material.

Sam - So where do I see this on my phone?

Francisco - One of the applications that these sort of laser markers are used, is for the marking of buttons or the logo of the company that sold you your phone. All those letters are basically made with the laser marker that's been removing a little bit of the material to give a bit of contrast.

Sam - And what else is this used for beside from phones?

Francisco - Well in industry, that will be used also for the dashboards on your car, all the digits that are there. Your keyboards as well. Laser markers are used for the clothing industry as well so they're able to make the garments look like they're older, or really make complex patterns with clothing, and they use a marker as well to remove the material and give you that finish that people like.

Sam - While the marker was running, Franscisco led me to a room next door with an enormous table filled with shiny, polished mirrors and impressive looking lenses.

Francisco - Okay Sam welcome to our ultrafast laser facilities. We basically remove material using a very short pulse laser in this room. Just to give you an idea of time, that will be around a million millionth of a second, give or take. So very short pulses and what this does to the material, it does not create heat compared to the other laser that you've just seen today. So with the other laser we usually create heat and we have heat zones around where the high intensity laser head, the metal in this case, that we were looking at. And in this lab - this laser - the pulses are so short that heat doesn't dissipate to the material. So that is one of the main advantages of this process.

Sam - With the heat unable to spread, the material that is left won't be damaged or melted. It was for work on the generation of lasers of this kind that Donna Strickland and Gérard Mourou were awarded the 2018 Nobel Prize in Physics. These lasers are capable of making cuts that are less than a micron wide - that's smaller than a thousandth of a millimeter. But what does ultrafast machining have to do with making parts for my phone?

Francisco - Well the laser is used to cut the glass that you have as a front screen, and it's also used to pattern the array that serves as a sensor for you to have a touch screen. Sometimes if you angle it right you can see the little patterns on your phone. And basically that's done with a laser because lasers are able to cut basically any material that you have. And it’s really hard to do with any other processes

Sam - So what makes lasers so good at doing these things?

Francisco - Well you have very tight tolerances, that means very high accuracy, when you're cutting parts. Think of the spot of the laser being, again, a tenth of your hair or smaller depending on which laser you use. So they're able to make very, very fine cuts; as well as there's no vibration. When you're cutting glass, that are very sensitive to that kind of things, you can really reduce the impact of machining and remove material basically from all these materials.

Sam - So what else do we use laser micro machining for?

Francisco - Well you have a lot of applications for these kind of lasers. So we can add material or remove materials, it depends on what you want. For the health industry, there’s little stents that are made via laser. To machine the solar panels that you see in houses. If you go to the cutting edge of this technology, we have it being introduced for plastic electronics. So next generation devices that we’re going to be having in the next years, this is one of the main processes and technologies that are going to be implemented.

Sam - So there's a host of uses, from medical implants to solar panels, for just this type of laser, not to mention those used in other manufacturing applications like welding. Just before I left Francisco had this fairly bold claim to add.

Francisco - I’m pretty sure that anywhere where you are you can see something that's been done with a laser.

Green printing

with Mark Pickford, Seacourt

Innovation is important for making new products, but also for developing new methods of making things we already have, in a more efficient and environmentally sound way. Mark Pickford is from the printing company Seacourt, based in Oxford, who are winning awards for the environmental turnaround that they’re bringing to the industry, and he spoke to Chris Smith about how the company works...

Mark - Fundamentally we’re a printing company so we’re producing everything from stationery, letterheads, business cards all the way through to corporate brochures annual reports, sustainability reports and we also manage a lot of work in terms of large formats. So we're producing large format for events: pop up stands and that kind of thing.

Chris - And why is the printing industry potentially a naughty player when it comes to the environment>

Mark - Well 90 percent of printing that your listeners will be seeing on an everyday basis is produced by the lithographic process. It's a process that uses lots of water. Chemicals are added to the water to make the water more usable and those chemicals are very high in volatile organic compounds. As well as the industry is run on printing presses - very high users of electricity, we generate a lot of waste and it's something that we've kind of as a business decided that we needed to take responsibility for.

Chris - So basically the embodied energy and the embodied water in turning out something as trivial as a newspaper or even a sheet of printed paper is huge and you want to try and change that?

Mark - Yeah absolutely

Chris - How are you trying to address that.?

Mark - We decided about 20 years ago to completely change the way that we did our business to take the environment really at its core. And the first thing we looked at was the actual process itself. And so we converted going from the standard lithographic process to a waterless offset process which basically eliminates the use of water. We've saved 8 million plus litres of water since we converted. More importantly, or as importantly certainly, we've completely taken out the the chemicals that are added to the water to make it more usable for the process.

Chris - And to be clear that water previously, given that it carried that toxic cargo, you couldn't just tip that down the drain, that would have had to have been remediated in some way.

Mark - So you've got not only the contamination but you also then have the power and the energy that you use to require it to get it back to a normal usable process so it's far reaching.

Chris - Now if this is so good because I mean it sounds wonderful not to make all this contaminated water not to use these other nasty chemicals. Why isn't anyone doing this?

Mark - A few years ago it was going to be the next big thing. But the trouble is to get a printing company to convert to a completely different process it can be financially ruinous, we were very lucky that when we decided to go down this route that we were at a point where we wanted to develop the company, we were at a size where we could be flexible. It requires completely changing the process, the machinery the training of all your staff, the environment of the actual factory itself. So it's a very difficult process to suddenly go from one to the other.

Chris - So the capital outlay is very very big so that would be an impediment to smaller businesses.

Mark - Yeah and into larger companies you know the printing industry like many industries, margins are very tight. You know there aren't great deals of money to invest on not producing anything for a month or two months while you convert to a completely different process.

Chris - So you've had to put up a lot of money to convert your process but now you've done that. Are you still competitive in the market can you still churn out print copy at a price that means you can compete.

Mark - Yes we can. We have overheads that are slightly higher than another printing company but the industry itself is on a race to the bottom in terms of pricing. So we would always argue that we are financially sustainable which is just as important as the environment if you like for business. We certainly aren't the cheapest in the country and we would never want to be but we are very competitive and we couldn't survive as a company in this market if we weren't competitive.

Chris - It's a sort of position that the industry the world over finds itself in isn't it whether the planet pays the price. Where do you end up - at the moment we're all hooked on oil because it's cheap and it's there and it means we can make stuff cheap we make loads of plastic for instance it does the job we want and at the moment while the planet pays the price we're comfortable to live with that. Actually it means we've got to be brave and daring spend some money and live with slightly higher production costs but then the planet doesn't pay the price ultimately and that's the sort of direction that you're taking isn't it.

Mark - Absolutely absolutely.

Chris - So you've sourced out the water problem. What other initiatives or innovations are you looking to introduce in the future.

Mark - There's many things that we've done already which is: zero waste to landfill since 2009, even our teabags and sandwiches are dealt with by a team of worms - red tiger worms.

Chris - They eat teabags? I thought teabags were a bit of a problem.

Mark - No, no they seem to do absolutely fine on that. I don't think they like garlic or onions. So we have to be a bit selective about what we leave behind but we've been running on 100 percent renewable energy for many years now. The whole process of the business is all about sustainability. We've looked at all of our staff. Anything to do with the business and how they're engaged with the business, how they get work, go through carbon offsetting schemes. We always believe that mitigation is far more important than offsetting so we've mitigated as much as we possibly can and then what we cannot mitigate, we offset through schemes in the Brazilian basin and that involves local communities in the production of acai berries. So we have a social, economic and environmental benefit to the planet which we've called Planet positive printing whereby whatever we produce actually has a net benefit to the environment rather than a negative impact on the environment.

Chris - And did you notice mark we put you on the green microphone?

Mark - I did notice that and thank you very much. I was going to bagsy it.

55:01 - Manufacturing the future

Manufacturing the future

with Professor Sir Mike Gregory, Cambridge University

What will manufacturing in the future look like? Georgia Mills put this to former head of Cambridge University's Institute of Manufacturing, Mike Gregory...

Mike - Well in some ways it's going to be the same, but better. To get a glimpse of modern manufacturing which we've had is I think given a flavour of the excitement of making things which isn't always obvious. Most of us don’t get the chance to get inside factories but we can see the products. So at home or on the way to work in the office or the factory or the hospital, you can see the output of manufacturing all around you and it's quite fun to think about how those everyday things have been made. And there’s a lot of the world around us which can be made better by better manufacturing, making things cheaper, more reliable more sustainably, so that we can bring the standards of living that we enjoy in the advanced countries to people all around the world. There's plenty to do. Manufacturing is not going to change but it's going to get a lot better.

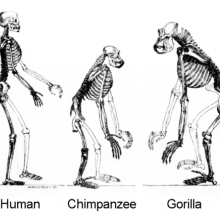

56:26 - When did we become modern day humans?

When did we become modern day humans?

With the help of Cambridge University's Professor Robert Foley, Sam Brown took a trip back in time to answer Stuart's question...

Robert - In evolutionary timescales, the answer is not very far. If we start the clock of human evolution at around 5 million years ago when the split from our last common ancestor with chimpanzees then probably up to around 200,000 years ago we would begin to see quite big differences. Before that not only would the babies look different but they would grow more rapidly and develop faster.

Sam - So being shorter and hairier, we might be able to pick them from a crowd. But what about behaviourally? Would they be able to function in today's society?

Robert - We don’t know enough in detail about their behaviour to say if they would stand out today. They would have probably learnt to speak, but perhaps not with the range of syntax and vocabulary we have. An interesting reason why we can’t be sure is that while people 200,000 years ago might not have had developed language like us, it could be that they would have had the mental capacity to learn it in a modern cultural setting.

We would probably have to go back to over half a million years ago to find them not speaking at all - perhaps the trait that would be most noticeable. It's a good question and echoes one I ask students, “If we found a living Neanderthal child should he or she be put in a school or a zoo?” Probably school, but what about earlier modern ancestors such as Homo erectus from 1 million years ago or Australopithecines at 3 million?

Sam - Fascinating stuff and another tricky question to finish off with too. But our forum users had even more to add. Halc suggests that one of the biggest challenges facing this time travelling infant would be growing up in the first place. He says the baby will not have the benefit of the last, say, million years of perpetual evolution between us and the stuff that's trying to kill us. The baby would have a hard time growing up at all since all these diseases that have bred to prey on humans will find the baby fairly defenceless. Well we better start working on some vaccines alongside that time machine then.

Comments

Add a comment